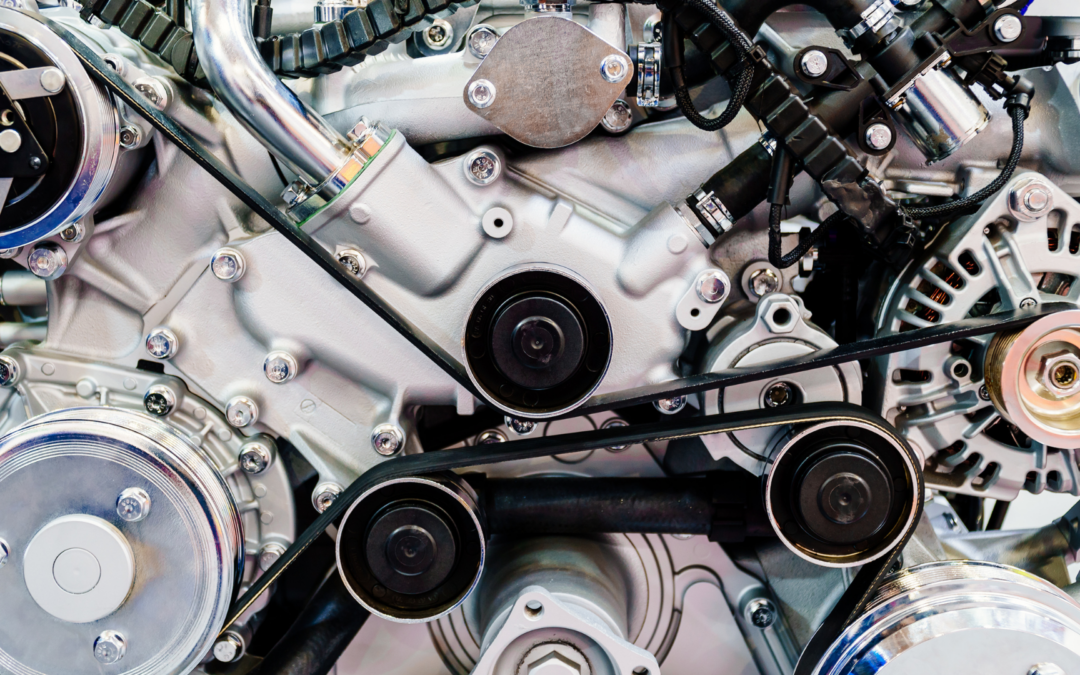

In the vast and intricate landscape of automotive engineering, there exists a marvel of ingenuity and power: the engine. Often referred to as the heart of the vehicle, the engine is a symphony of moving parts and controlled explosions, converting fuel into motion with remarkable efficiency. At All Around Auto Repair, we believe that understanding the inner workings of your engine is essential for every driver. In this comprehensive guide, we’ll take a deep dive into the main components of an engine and how they work together to propel you down the road.

The Anatomy of an Engine:

Before we delve into the intricacies of engine functionality, let’s first familiarize ourselves with its main components:

- Cylinder Block: This is the foundation of the engine, housing the cylinders where combustion takes place. The number of cylinders varies depending on the engine type, with configurations ranging from inline-four to V12.

- Pistons: Inside each cylinder, you’ll find a piston – a cylindrical component that moves up and down in response to combustion forces. Pistons are connected to the crankshaft via connecting rods and are responsible for converting the pressure generated by fuel combustion into rotational motion.

- Crankshaft: As the pistons move up and down, they transfer their motion to the crankshaft via connecting rods. The crankshaft, in turn, converts this linear motion into rotational motion, which drives the transmission and ultimately the wheels.

- Valve Train: The valve train consists of valves, camshafts, and associated components responsible for controlling the flow of air and fuel into the cylinders and the exhaust gases out of the cylinders. This precise timing is crucial for engine performance and efficiency.

- Fuel System: The fuel system delivers a precise mixture of air and fuel to the cylinders for combustion. It typically consists of components such as fuel injectors, throttle body, fuel pump, and fuel filter.

- Cooling System: To prevent overheating, engines rely on a cooling system that circulates coolant (usually a mixture of water and antifreeze) through the engine block and cylinder head, dissipating heat and maintaining optimal operating temperatures.

- Lubrication System: Engine components experience high levels of friction and heat during operation. The lubrication system ensures smooth operation by distributing oil to critical engine parts, such as bearings, pistons, and camshafts, reducing wear and tear.

How It Works: The Four-Stroke Cycle

Now that we’ve acquainted ourselves with the main components, let’s explore how they work together to generate power. Most modern engines operate on the four-stroke cycle, also known as the Otto cycle, which consists of four distinct phases:

- Intake Stroke: As the piston moves downward, the intake valve opens, allowing a mixture of air and fuel to enter the cylinder. This phase creates the necessary fuel-air mixture for combustion.

- Compression Stroke: With both valves closed, the piston moves upward, compressing the fuel-air mixture into a smaller volume. This compression increases the mixture’s pressure and temperature, preparing it for combustion.

- Power Stroke: At the top of the compression stroke, the spark plug ignites the compressed fuel-air mixture, causing a controlled explosion. The rapid expansion of gases pushes the piston downward with considerable force, generating power.

- Exhaust Stroke: As the piston reaches the bottom of the power stroke, the exhaust valve opens, allowing the burned gases to exit the cylinder. The piston then moves upward, pushing the remaining exhaust gases out of the cylinder.

Advanced Engine Technologies

In addition to the traditional four-stroke cycle, modern engines incorporate advanced technologies to improve efficiency, performance, and emissions. Some of these technologies include:

- Direct Injection: Unlike traditional port fuel injection, direct injection delivers fuel directly into the combustion chamber, resulting in better fuel atomization, improved combustion efficiency, and reduced emissions.

- Variable Valve Timing (VVT): VVT systems adjust the timing of the intake and exhaust valves to optimize engine performance under different operating conditions. This improves power delivery, fuel efficiency, and emissions control.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, compress the incoming air to increase its density, allowing the engine to produce more power without increasing displacement. This technology is commonly used to improve performance in smaller, more fuel-efficient engines.

- Hybrid and Electric Powertrains: With the rise of electric and hybrid vehicles, engines are being integrated into more complex powertrain configurations. Hybrid systems combine internal combustion engines with electric motors to improve fuel efficiency and reduce emissions, while fully electric vehicles rely solely on electric propulsion.

Conclusion: The Engine’s Endless Evolution

In conclusion, the engine is a marvel of engineering ingenuity, continuously evolving to meet the demands of performance, efficiency, and environmental sustainability. By understanding its main components and how they work together, drivers can appreciate the intricacies of this vital automotive component. At All Around Auto Repair, we’re committed to helping drivers maintain and optimize their engines for peak performance and longevity. Whether it’s routine maintenance or complex repairs, our team of skilled technicians is here to ensure that your engine remains the beating heart of your vehicle for years to come.